Creating a Work Order Plan

Guide

The manufacturing module revolves around the Work Order. The Work Order is the plan or document that is given to the manufacturing line or shop floor as the trigger to manufacture a certain quantity of an item. The following diagram illustrates how the Work Order is used to create Job Cards and Stock Transfer forms. In this tutorial, it is assumed you have already created a Work Order and are now ready to start producing against it.

Transfer Raw Materials to WIP

Log into your ERPNext account

Click on Manufacturing > Work Order

Go to Work Order. Select the Work Order created.

On the Work Order Dashboard, Click Start.

Enter the Qty for Material Transfer to Manufacture. Click “Create”.

A Stock Entry Document “Material Transfer for Manufacture” will be created.

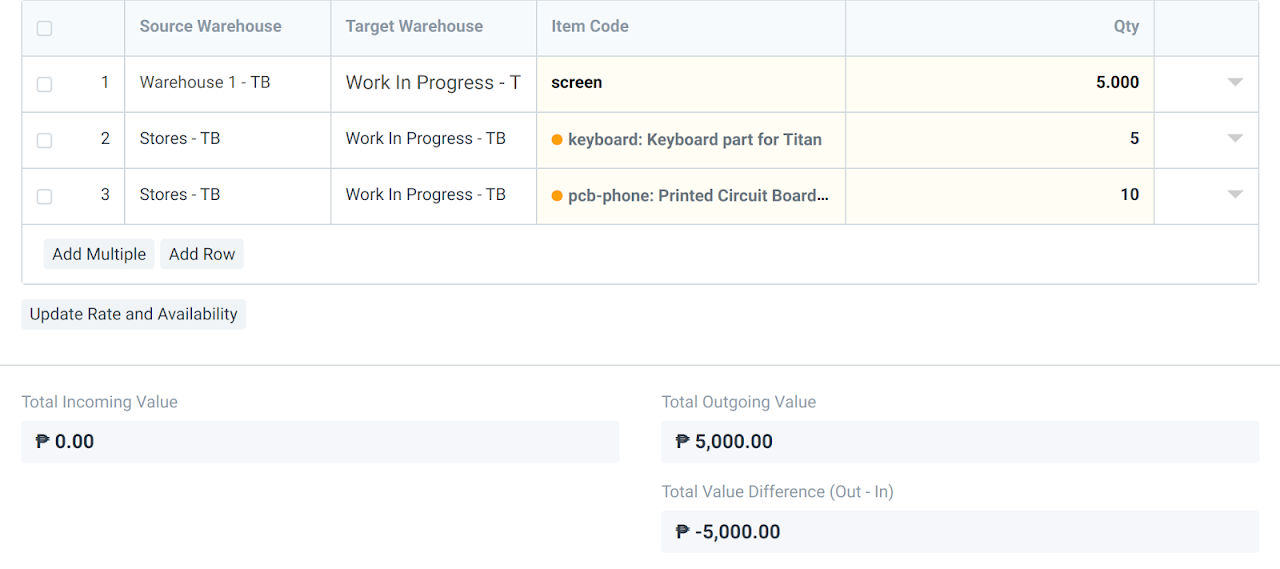

Raw materials included on the BOM multiplied by quantity to manufacture will be automatically fetched on the stock entry document.

Add the target WIP warehouses for each of the Raw Materials.

Review the Source and Target Warehouses and the Total incoming and outgoing value of the raw materials.

10. Click Save or press CTRL+S to save the document. Note that this does not finalize the document yet. Instead, it saves the Stock Entry form in draft status

11. If everything is in order, click on Submit.

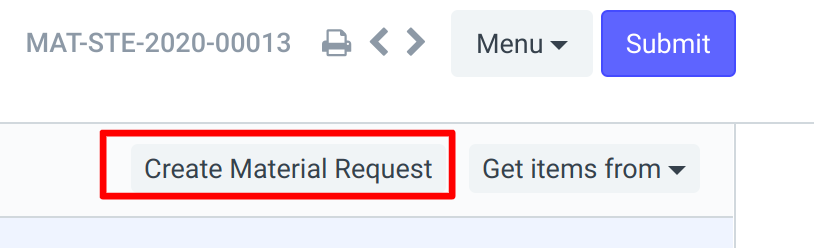

Note: If the raw materials inventory is not sufficient and need to make a material request/purchase, you can click the “Create Material Request” button and a Material Request Document will be created with the items identified in BOM.

Job Card

Log into your ERPNext account

Click on Manufacturing>Work Order.

Under the Work Order, select the Work Order you would like to process the Job Card for.

Click Job Card. This should display the Operations assigned on the BOM for the item that will be produced.

Click the Job Card to be processed first.

Click Start Job, then Complete Job when job is done.

Alternatively, you can also fill the From Time and To Time in the Time Logs table.

Enter the Completed Quantity. This is the number of Items on which the Operation was performed for the selected time interval.

Add more rows in the Time Logs table and record time using the Start/Completed buttons if necessary.

Click Submit.

Keep in mind: Job Card completion will change the production status in Work Order, you can track the completion of production progress for each of the Operations defined in the Work Order.

Manufacture and Transfer Finished Goods

Once Stock Entry of Raw Materials and Job Card are finished, click Finish from the Work Order Dashboard.

Enter the Qty for Manufacture and click “Create”.

A new Stock Entry Document “Manufacture” will be created.

Raw Materials consumed and Finished Goods will be displayed on the item table. Review the Target Warehouse where the Finished Goods will be transferred.

Keep in mind: After a BOM is submitted, it cannot be edited. This is because a BOM is linked to multiple forms in the manufacturing module. You can only cancel the existing or duplicate it. An item can have more than one BOM.

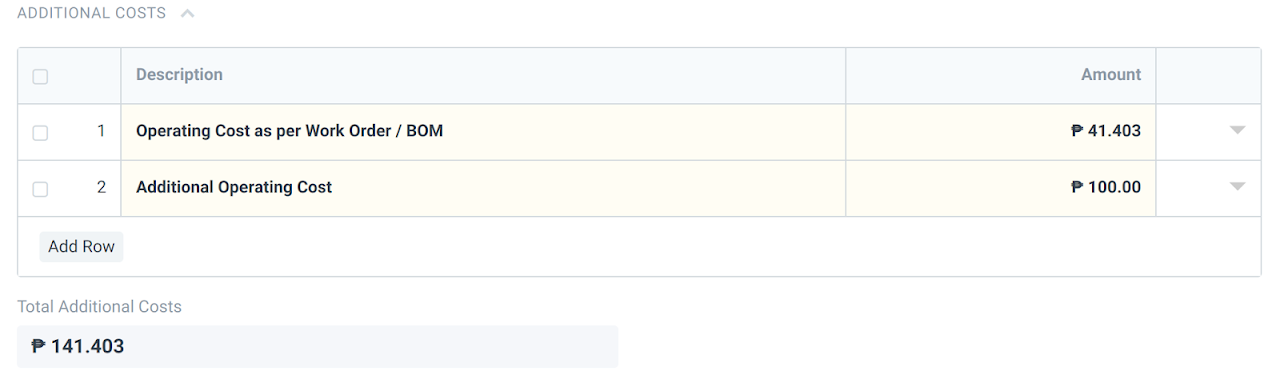

5. Operation and Additional Operation Costs will also be included on the document. This will be included in the total Finished Good cost.

6. Click Save or press CTRL+S to save the document. Note that this does not finalize the document yet. Instead, it saves the Stock Entry form in draft status.

7. If everything is in order, click on Submit.

8. Going back to the Work Order, Status Dashboard will be changed to Green (Completed). Number of Quantity Produced will be displayed.